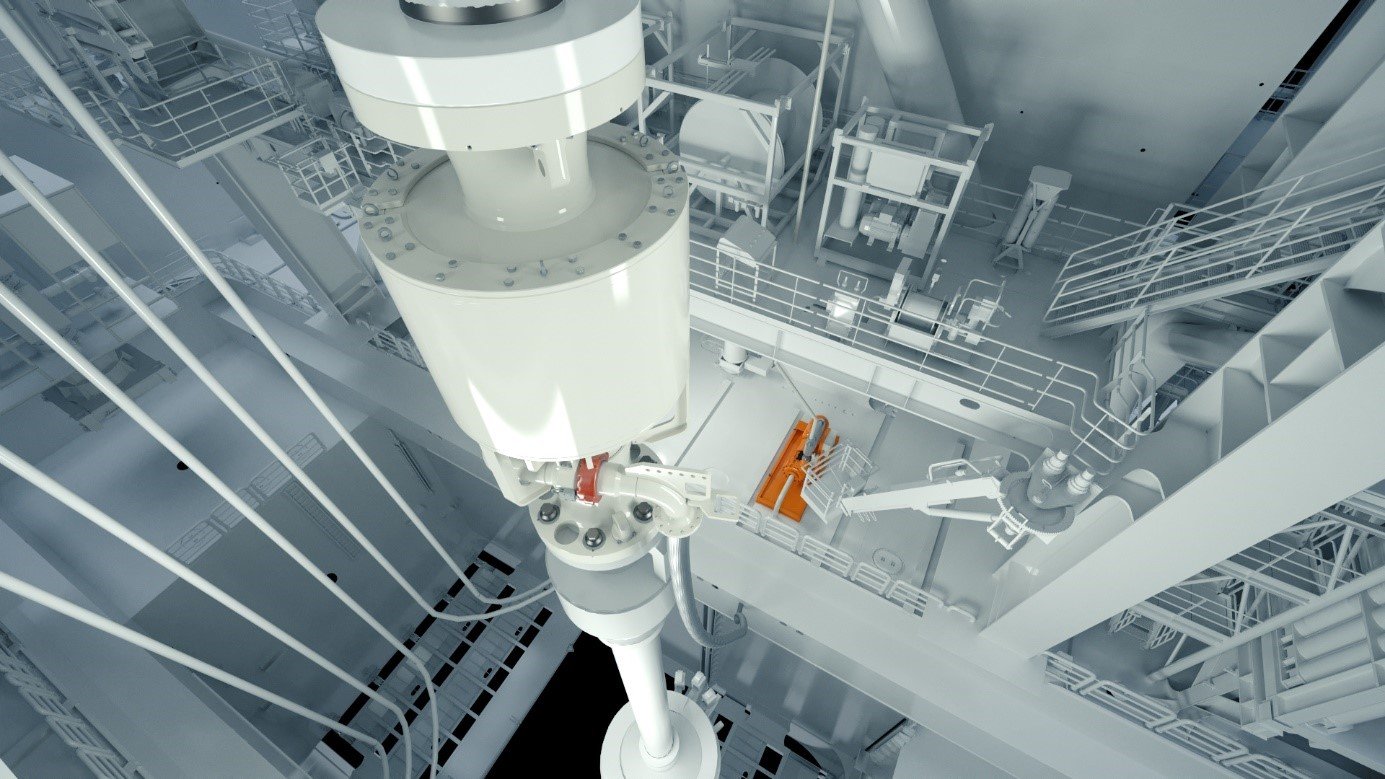

ENHANCED DRILLING together with partner Transocean, has developed a new Enhanced Kick Detection system (EKD). The system eliminates the external effects of rig and slip-joint motion, to give a highly accurate return volume flow measurement enabling rapid detection of flow anomalies, resulting in reduced time spent on flow-checking.